Industrial Marine Supplies

Discover the Strength of Industrial Marine Solutions

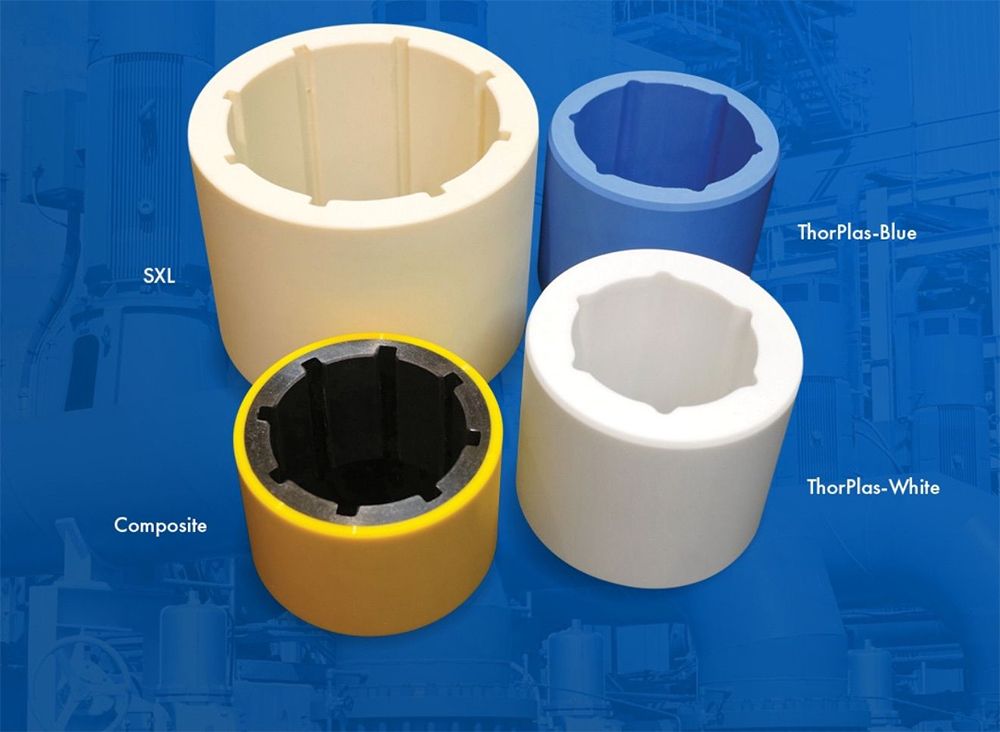

At Canyon Marine Solutions, we're more than just an industrial supply store. We're your partner in navigating the rough waters of industrial facility needs. Our range of bearings includes:

- SXL

- Thorplas White

- Thorplas Blue

- Thordon Composite

- Thordon XL

- Thordon SXL and HPSXL

They're easy to install, built to last, and backed by our fast, on-site service. Plus, they're environmentally friendly, making them a choice you can feel good about. Call or text us today.

Why Choose Canyon Marine Solutions?

When it comes to industrial bearings, bushings, and seals, we understand you have options. But at Canyon Marine Solutions, we believe we offer something different. Our self-lubricating, non-metallic products are designed for easy installation, extended wear life, and without the need for any oil or grease.

They're also made to last, offering you long-term value and peace of mind. And with our fast, on-site service, you'll never be left stranded.

Get in touch with us.

Share On: